Simplified energy storage sizing and selection

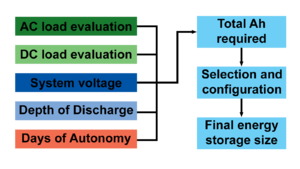

The energy storage system is sized based upon the average daily energy requirements for the system. The preliminary steps of this process output a suggested Ah size for the energy storage system, but then it is necessary to determine a series and parallel configuration based upon the available battery voltages and sizes.

Assumptions:

- Lead acid batteries are used.

- Batteries will be discharged to 50% depth of dischrage.

Contents

Step 1: Determine days of autonomy parameter

The days of autonomy parameter determines the number of days that the system will be able to meet energy needs without additional charging of any kind. 1 day of autonomy provides enough energy storage capacity to provide energy for the loads from the simplified load evaluation for 1 day without any additional charging. Each additional day of autonomy adds an additional day of energy storage capacity. For example:

- 205 Ah lead acid battery x 1 day of autonomy = 205 Ah

- 205 Ah lead acid battery x 2 days of autonomy = 410 Ah

- 205 Ah lead acid battery x 3 days of autonomy = 615 Ah

The value that is chosen for this parameter depends largely upon the variability of the solar resource, the intended use of the system, and the budget. It is almost always preferable to have additional storage, therefore budget often becomes the primary constraint. There are various considerations that go into determining the value that is appropriate for a particular design:

- If a system is intended for a location where the weather or solar resource is highly variable, the value for days of autonomy should be increased.

- If a system is intended to provide power at a location where the users will adjust their energy consumption according to the weather or that is used infrequently, fewer days of autonomy can be built into the system. A value of 2 days of autonomy may be appropriate in these cases as long as there is a sufficiently sized PV source or an additional form of generation.

- If a system is intended to provide power at a location that must operate continually, like at a health clinic, it is recommended that a significant number of days of autonomy are built into the system or that an additional form of generation, like a generator, is added to the system. An energy storage system with 5-7 days of autonomy for a health clinic will often be quite substantial in size, difficult to charge properly, and costly. Therefore, a backup generator should be considered in this case.

- The days of autonomy value that is chosen will be used to size the energy storage system to meet energy demand when the system is new, but the storage capacity will gradually decline over time. Therefore, oversizing the energy storage system to take this into account is a good idea.

Step 2: Determine minimum Ah value

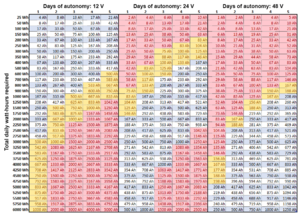

Using the chart below, find the minimum recommended Ah value based upon the DC system voltage and the Total daily watt-hours required. Cells highlighted in red are not recommended configurations - a higher or lower DC system voltage should be used. Cells highlighted in yellow situations are questionable configurations - a higher or lower DC system voltage should be considered. These recommendations are based upon commonly available battery sizes, equipment availability, and the best practice of using a low number of parallel battery circuits (a maximum of 3 is recommended).

Step 3: Adjust minimum Ah value for the minimum temperature

The minimum Ah value (Step 2) must be adjusted for the minimum temperature that the batteries will reach during operation. The temperature of lead acid batteries has a significant effect upon performance. When lead acid batteries reach a temperature below 25°C, their usable capacity begins to decline. This can lead to batteries being deeply discharged and damaged, therefore the size of the energy storage system should be adjusted to ensure that there is adequate energy available at the minimum expected indoor temperature for the location. The temperature correction factor is just an estimation that allows the energy storage system to be increased in size to account for lower temperatures. Temperature correction factors for various battery types at varying temperatures:[1]

| Temperature | FLA | AGM | Gel |

|---|---|---|---|

| 25°C | 1.00 | 1.00 | 1.00 |

| 20°C | 1.06 | 1.03 | 1.04 |

| 15°C | 1.13 | 1.05 | 1.07 |

| 10°C | 1.19 | 1.08 | 1.11 |

| 5°C | 1.29 | 1.14 | 1.18 |

| 0°C | 1.39 | 1.20 | 1.25 |

| -5°C | 1.55 | 1.28 | 1.34 |

| -10°C | 1.70 | 1.35 | 1.42 |

| Temperature adjusted minimum Ah required | = Minimum Ah value (Step 2) × Temperature correction factor |

|---|

Step 4: Determine battery voltage, Ah rating and wiring configuration

Choose a battery based upon what is available in the market to proceed with the design. Lead acid batteries are commonly available in 2V, 4V, 6V, 12V designs that can be wired in series to achieve a 12V, 24V, or 48V system voltage. See Battery wiring for more information on how to properly configure a battery bank. With small systems 12V batteries are the standard, but as system size increases lower battery voltages lead to more storage with fewer parallel strings, which is a better design. Deep cycle batteries with voltages below 12V can be difficult to find in some locations.

| Batteries in series | = DC system voltage ÷ Chosen battery voltage |

|---|

Lead acid batteries are available in a variety of Ah ratings. They can be wired in parallel to achieve the desired total Ah of storage for the system. The result of this calculation should be rounded up, meaning that if the number of parallel strings is more than 1, then 2 parallel strings are required. The other option would be to use a battery with a higher Ah rating.

| Number of parallel battery circuits | = Temperature adjusted minimum Ah required (Step 4) ÷ Chosen battery Ah rating |

|---|

Step 5: Calculate final Ah capacity

The final Ah capacity of the battery bank is the chosen battery Ah rating multiplied by the number of parallel strings. This value is important for other calculations in the design process.

| Final Ah capacity | = Number of parallel battery circuits (Step 4) × Chosen battery Ah rating (Step 4) |

|---|

Notes/references

- ↑ Trojan Battery Company - Battery Sizing Guidelines https://www.trojanbattery.com/pdf/TRJN0168_BattSizeGuideFL.pdf