Lead acid battery

Lead acid batteries rely on reversible chemical reactions between lead and acid to provide energy when it is needed and to store energy when it is being produced. They have been around for over 150 years and have proven their durability, low-cost, recyclability, and performance under variable conditions to the point that nearly every automobile on the planet relies on a lead acid battery to start and run. Lead acid batteries have been the preferred form of energy storage for off-grid PV systems since they first began being built for the previously mentioned reasons, thus most off-grid PV components are built for use with lead acid batteries in 12 V, 24 V or 48 V configurations. Lead acid batteries have the added advantage of coming in a variety of voltages (2 V, 6 V, 8 V, 12 V) and amp-hour ratings (5 Ah to 5000+ Ah). But due to their high density of lead, these batteries are extremely heavy. A 12 V, 225 Ah flooded lead acid battery weighs around 60 kg, which is approaching the upper-limit of what is easily movable without equipment.

Just like how a PV module is comprised of various different PV cells connected together in series that each produce a certain voltage, lead acid batteries are composed of series connected cells with each one producing around being having a nominal voltage of roughly 2 V. This means that a 12 V battery will consist of 6 cells.

There are many different types of lead acid batteries, but they can initially be divided into two categories: starter batteries and deep-cycle batteries.

- Starter batteries are used in cars and are intended to provide large amounts of power for short periods of time with a shallow depth of discharge. They work well for this purpose, but they are unable to continuously supply power beyond a shallow depth of discharge without severely shortening their cycle life. These batteries will fail prematurely in a PV system and are not worth investing in.

- Deep-cycle batteries have a more robust design that enables them to continuously supply high amounts of power to a deeper depth of discharge - generally considered to be around 80%. These batteries are heavier and cost more than starter batteries but are the appropriate battery for use with a PV system.

There are various different types of lead acid batteries, but this page will focus on the two main categories: flooded lead acid (FLA) and valve regulated lead acid (VRLA) deep-cycle batteries.

Contents

Flooded lead acid (FLA)

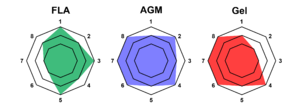

(1) Energy density (2) Power density (3) Cost (4) Safety (5) Cycle life (6) Temperature range (7) Maintenance (8) Efficiency

The original lead acid battery design. They are the simplest, most durable, and cheapest of the lead acid batteries. They are slightly more durable as they tend to be more forgiving of deep discharges than maintenance-free VRLA batteries.

Characteristics:

- They require monthly maintenance as the batteries will lose water as they charge and discharge. Durable, long cycle life and cheap only if properly maintained. If maintenance is not performed regularly, the batteries will rapidly fail, and replacement will cost significantly if maintenance-free batteries had been used initially.

- Release significant amounts of hydrogen gas.

- Have a liquid electrolyte solution inside that requires that they remain upright.

- Can undergo an equalization charge which can help to prolong their cycle life by reducing sulfation.

Considerations for use:

- End users that are capable of maintaining a battery (with proper training and protective equipment) or in a location where the system can be serviced by technicians.

- Users must have reliable access to distilled water was any other form of water has impurities and will damage the battery over time.

- Require a secure space with proper ventilation due to the combined hazard of the batteries spilling acid and their tendency to release significant amounts of hydrogen gas. They also create a noxious sulfur smell. The combination of these risks means that ideally flooded batteries should always be stored in a room that is secure and not regularly inhabited like a storage room, shed, or garage.

- May not be the best battery type with either extreme high or low temperatures.

- Low budget and high energy needs.

Valve-regulated lead acid (VRLA)

In the 1970's valve-regulated lead acid batteries began to enter the market. These batteries solved many of the major faults with flooded lead acid batteries: they are maintenance-free, they do not have a liquid acid electrolyte that can be spilled, and they do not expel significant amoutns of hydrogen. There are trade-offs though: they are less durable because they are not as tolerant of deep discharges, they have a shorter cycle life and they cost significantly more than flooded lead acid batteries. There are two primary sub-categories of VRLA batteries: Absorption glass mat (AGM) and Gel.

Characteristics:

- They do not require maintenance.

- They are sealed (although not completely) so there is little to no off-gassing.

- They do not have a liquid electrolyte solution inside and are additionally sealed to prevent leaks, therefore they do not have to be positioned upright at all times.

Considerations for use:

- End users that may not perform maintenance.

- Locations in which there is not a separate space that can be dedicated to energy storage. These batteries cannot create hazardous spills, emit significant amounts of hazardous gases, or emit a noxious sulfur smell. They still should be securely stored in a battery box, but they can be located in a multi-use space if necessary.

- Require a higher budget.

Absorption glass mat (AGM)

A VRLA battery in which the electrolyte solution is contained within mats of fine glass fibers. These batteries cost on average 1.5-2 times as much as FLA and have a shorter cycle life when compared to a properly maintained FLA battery.

Specific considerations for use:

- Permit higher charge and discharge rates than FLA and gel batteries.

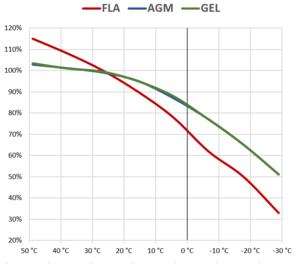

- Perform better than FLA and gel batteries in cold environments. FLA batteries can freeze and be damaged during charging and discharging.

Gel

A VRLA battery in which the electrolyte solution is made into a gel paste. Gel batteries are the costliest lead acid option. They prefer slow charging and discharging, which is not ideal for renewable energy systems that often do both everyday.

Specific considerations for use:

- Perform better than AGM and FLA batteries in hot environments.

Storage capacity

The storage capacity of a lead acid battery is measured in amp-hours (Ah). The amount of this energy that is actually usable energy depends upon:

- The rate at which energy is withdrawn. If a battery lead acid battery is discharged rapidly, the amount of usable energy decreases. Conversely, if discharged slowly, the usable energy increases. This is measured in in terms of C-rate. A C-rate of 1 means that the entire capacity of the battery is discharged in 1 hour. A C-rate of 20 or C/20 means that the entire capacity of the battery is discharged over the course of 20 hours. Lead acid batteries are typically rated by their C/20 rate. Below is an example for a Trojan 12 V 205 Ah AGM battery:[2]

C-rate Amp-hours 10 hour 174Ah 20 hour 205Ah 48 hour 210Ah 72 hours 213Ah 100 hours 216Ah

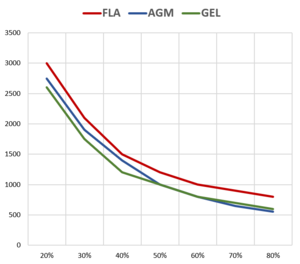

- The chosen depth of discharge limit for a battery. The cycle life of a battery depends greatly upon how deeply it is discharged and how frequently. The numbers of cycles vary depending upon the type of battery as well.

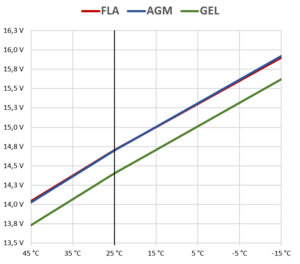

Temperature

The temperature of a lead acid battery or battery cell directly influences its resting voltage and the voltages at which it should be charged. It is worth noting that batteries have significant thermal mass, so brief periods of high or low ambient temperatures do not tend to quickly change battery temperature on their own. Batteries do internally generate heat as they charge and discharge.

Higher temperatures give batteries an increased capacity, but also greatly shortens their life. For lead acid batteries it is estimated that for every 10°C increase in average temperature above 25°C shortens the batteries life by half. This means that operating a lead acid battery for one month at 35°C is equivalent in terms of battery life to operating the battery for two months at 25°C[2].

Low temperatures decrease the capacity of all lead acid batteries can leave them prone to damage during charing and discharging. Extremely low temperatures can cause flooded lead acid batteries to freeze, which can crack the case of the battery and cause electrolyte to spill. The freezing point of flooded lead acid batteries varies with their state of charge. For all lead acid batteries it is important to use them lightly if they are at a very low temperature (below -10°C).

Locating the batteries in an appropriate location and properly storing them is essentially to ensure that a system performs properly. A charge controller that is able to take into account battery temperature through a remote sensor can greatly prolong battery life and avoid accidental overcharging that can severely damage batteries.

Efficiency

There is no type of storage that is perfectly efficient. Lead acid batteries inherently lose some energy as it is put into the battery and some as it is withdrawn, generally as heat. A FLA battery is typically only 80-85% efficient, whereas a VRLA battery is has a slightly higher efficiency of 85-90% efficiency. This is round -trip efficiency, meaning that if 100Wh of energy arrives from a PV module is stored in a lead acid battery that:

- 80-85 Wh will be able to be withdrawn from the FLA battery.

- 85-90 Wh will be able to be withdrawn from the VRLA battery.

Charging

Lead acid batteries have specific charging requirements that must be followed to ensure that they continue functioning for a their rated cycle life. For more information on the the different charging phases - see Charging phases.

Sulfation

It is important that batteries reach a full state of charge (90-100%) on a regular basis. If batteries do not reach a full state of charge every few days, then the plates within the battery will begin a process of sulfation which is the buildup of sulfate crystals on the plates of the battery that will start to impede performance and can ultimately lead the battery to cease functioning. Although a 30% depth of discharge is rather shallow for off-grid systems, if a battery regularly sits at 70% state of charge (the inverse of a 30% DoD) the batteries will begin to sulfate, lose performance, and fail prematurely.

It is necessary to build a system with a PV charging source that can supply sufficient current to bring the batteries up to charge regularly while loads continue to operate. With FLA batteries it is possible to do a monthly equalization charge to reduce sulfation, but this is not possible with VRLA batteries.

Charge rate

If an off-grid PV system will rely solely upon PV as a charging source (no generator, no other renewables) then it is necessary to ensure that a PV source is properly sized for this role. The PV source size should be checked to ensure that it can supply sufficient current to properly charge the energy storage system. If lead acid batteries do not regularly receive an adequate charging current - typically because the PV source is undersized relative to the energy storage system - they will begin to experience sulfation and they will last for fewer cycles.

Lead acid batteries last longer and perform better when they are regularly recharged with a current in a certain range - typically between 5-13% of their C/20 rating.[6][7] It is best practice to consult the manual or manufacturer for recommended maximum and minimum charging currents. If a system uses many loads during the day, this will limit the available charging current for the energy storage system and should be taken into account.

- A minimum of 5% of the C/20 Ah rating is recommended for a system that is used infrequently or is primarily used at night.[6][7]

- A 10% of the C/20 Ah rating is recommended for a system that is used regularly with significant load usage during the day.

- A maximum of 13% of the C/20 Ah rating is recommended for gel and flooded lead acid batteries. A maximum of 20% of the C/20 rate Ah rating is recommended for AGM batteries..[6]

Discharge rate

Lead acid batteries have a recommended maximum continuous discharge current which is typically the same as the maximum charge current of the battery. This rate can be exceeded for brief periods of time when surge loads are operating or a heavy load, like a well pump, is operating for a few minutes, but the size of the energy storage system should be increased if the amount of current that the inverter will require to operate at its continuous duty rating exceeds the recommended value for the battery. Commonly used values for the maximum continous discharge current for different lead acid batteries are as follows:[6]

- A maximum of 13% of the C/20 Ah rating is recommended for flooded and gel batteries.

- A maximum of 20% of the C/20 Ah rating is recommended for AGM batteries.

It is important to consult the manufacturer of a particular battery as there are batteries that permit higher charge or discharge currents.

Battery storage

Due to safety issues posed by batteries (high available current, hazardous gases, dangerous chemicals) it is always necessary to put batteries in a secure enclosure or room to avoid unauthorized access to them. For small-scale off-grid systems they are typically housed in a battery box that is constructed to the required size of the battery bank. The most common and easy to work with material in most areas is wood, but it is also possible to build a suitable enclosure out of metal or plastic. Batteries should be checked regularly and serviced as needed, therefore it is important that any type of enclosure that they are placed into provides sufficient working space.

Location and security

Batteries must be placed in a location that will provide adequate cooling, a dry environment, and protection from unauthorized access. It is best practice to avoid installing batteries or other electrical equipment in living quarters meaning bedrooms, kitchens, or living rooms. This is especially true with flooded lead acid batteries as they generate a noxious sulfur smell during charging. This is often not possible in many locations due the lack an additional appropriate space or concerns over theft. In this case, using VRLA (sealed) batteries and installing them in the living room would be preferrable to a bedroom or bathroom.

If a battery box is to be placed in an accessible location, then it is necessary that it has a means to avoid unauthorized access, like a lock. If the batteries are in a room without a battery box, it is necessary that the room itself be locked to avoid unauthorized access. A battery box should not be become means for storage - adequate space should always be left so that the lid can easily be opened without the need to move other items. Many batteries come with a rubber or plastic cover for the terminals, this can be a useful safety measure to prevent accidental short-circuits from accidents like tools being dropped across the terminals.

Ventilation

FLA batteries release potentially explosive hydrogen during charging, therefore it is recommended that they are stored in a location with adequate free airflow. This is additionally important for cooling. If batteries are to be placed in a battery box, then holes should be made near the top and bottom of the box to enable rising hydrogen - which rises because it is lighter than most other molecules - to escape and other air to enter. A sloped lid on the battery box can help to improve ventilation. It is also a best practice to locate the point where any cables exist near the bottom of the battery box to avoid any hydrogen entering the conduit and making its way to the other electrical equipment.

AGM batteries do not release hydrogen during normal charging, but it would nonetheless be a good practice to follow the same practices recommended for batteries. At the minimum they should be provided good ventilation to provide appropriate cooling to avoid overheating during charging.

Spacing between batteries

Adequate spacing is important to permit adequate cooling of batteries and to permit safe working conditions. In cool climates - maximum temperature indoors under 30°C - a battery bank should allow for:

- At least 2.5 cm should be left between batteries.

- At least 15 cm of perimeter around the batteries. This may be 15cm between the batteries and the sides of the battery box or 15cm between the batteries and the nearest object if they are not in a box.

In warmer climates, more spacing can be provided and additional considerations should be taken to ensure adequate battery cooling. In cooler climates, insulating the battery box may be an appropriate choice to improve performance and prevent freezing.

Spill containment with FLA batteries

As FLA batteries contain an acidic electrolyte in liquid form, it is common for them to overflow during maintenance or if they are over-charged. It is important to build a spill containment system that can handle the amount of electrolyte that a battery bank could potentially spill. Placing the batteries in a plastic or rubber tray with a tip of at least 5 cm is recommended.

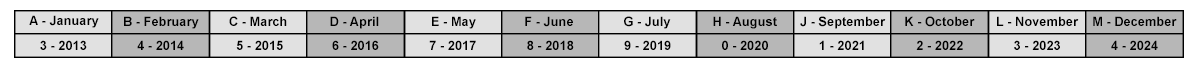

Date of battery production

It is important to understand the age of batteries when purchasing them and when servicing them. Batteries use a unique dating system. The month of production corresponds to a letter - beginning with "A" for December. The letter "I" is skipped due to its similarity to the number "1." The year of production corresponds to a number with "0" being the first year of a decade. For example a batter produced in March of 2018 would have a date code of "C8."

Safety

Lead acid batteries contain lead and acid, both of which are hazardous if they come into contact with the skin or are ingested. Installing, maintaining, or troubleshooting lead acid battery banks requires that appropriate personal protective equipment is worn at all times with the bare minimum being eye protection and gloves. Baking soda and water should always be stored in case of contact with the acidic electrolyte solution or if a spill were to occur. Baking soda is a basic substance, which is the opposite of an acid, and will work to neutralize the hazardous effects of the acid. Water works to dilute the acid and wash it away to minimize damage. If acid comes into contact with eyes or skin, baking soda can be applied and then area should be washed thoroughly and continuously for at least 15 minutes to dilute and remove the acid. If electrolyte solution comes into contact with clothing, it should also be neutralized with baking soda and diluted or else it will eat away the clothing. It is a good practice to store the appropriate personal protective equipment, baking soda, and water in the same location where with the batteries. After working with lead acid batteries, even if gloves were used, hands should be washed thoroughly to remove lead with which they may have accidentally come into contact.

For more information on electrical safety when working with batteries see: Electrical safety with batteries.

Recyclability

Lead acid batteries contain lead and acid, both of which are hazardous materials that must be disposed of properly[8]. Lead acid batteries are often pointed to as a success story for recycling as the majority of lead is used for batteries and an estimated 95-96% is ultimately recycled[9]. This largely has to do with a well-developed market, supply chain and abundant processing facilities for lead acid batteries as lead is a valuable material and is readily recyclable. This knowledge has spread and has resulted in batteries being returned for cash in even the most remote places.

Notes/references

- ↑ Trojan Battery Company - Selecting the Proper Lead-Acid Technology http://www.trojanbattery.com/pdf/Trojan_AGMvsFloodedvsGel_121718.pdf

- ↑ 2.0 2.1 Trojan Battery Company - Specifications sheet for 12 V 205 Ah AGM battery https://www.trojanbattery.com/pdf/SAGM_12_205_AGM_DS.pdf

- ↑ 3.0 3.1 3.2 Trojan Battery Company - Specifications sheet for FLA batteries https://www.trojanbattery.com/pdf/Signature_Trojan_ProductLineSheet.pdf

- ↑ 4.0 4.1 4.2 Trojan Battery Company - Specifications sheet for AGM batteries https://www.trojanbattery.com/pdf/AGM_Trojan_ProductLineSheet.pdf

- ↑ 5.0 5.1 5.2 Trojan Battery Company - Specifications sheet for Gel batteries https://www.trojanbattery.com/pdf/GEL_Trojan_ProductLineSheet.pdf

- ↑ 6.0 6.1 6.2 6.3 Trojan Battery Company - User's Guide https://www.trojanbattery.com/pdf/TrojanBattery_UsersGuide.pdf

- ↑ 7.0 7.1 The maximum charging current for most lead acid batteries is around 13% of the C/20 rate. Rolls Battery - Battery User Manual https://rollsbattery.com/public/docs/user_manual/Rolls_Battery_Manual.pdf

- ↑ GIZ report on End-of-Life Management of Batteries in the Off-Grid Solar Sector https://www.giz.de/de/downloads/giz2018-en-waste-solar-guide.pdf

- ↑ United Nations Enviromental Program report on recycling metals https://wedocs.unep.org/bitstream/handle/20.500.11822/8702/Recycling_Metals.pdf?sequence=1&isAllowed=y

Hydrowires - Energy Storage Technology and Cost Characterization Report

Isidor Buchman - Batteries in a Portable World

Thomas Reddy - Linden's Handbook of Batteries, 4th Edition