Difference between revisions of "Conductor types"

m (Alex moved page Wire and cable types to Types of wire and cable) |

|

(No difference)

| |

Revision as of 11:29, 27 November 2020

Wire and cable allows the safe transport of electricity between all of the different components of an electrical system. Wire refers to a single conductor whereas cable contains various wires within an additional layer of insulation protecting them. The conducting material of a wire may be copper or aluminum and its size varies based the amount of current that it will be required to carry, the voltage and the conditions. Copper wire is almost exclusively used for working with PV systems as it can carry more current for the same size wire and is easier to bend/work with. Wire insulation made of plastics or rubber and varies in color depending upon the application and location. It will also vary in thickness depending upon the voltage rating of the wire as a higher voltage rating will require additional insulation.

Contents

Wire types

Besides their maximum current rating, wires have additional other classifications.[1]

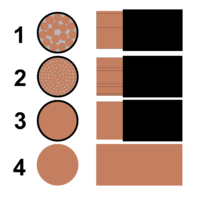

Stranding

- Stranded - standard stranded cable is the most commonly used type of wire as it is easy to work with under most circumstances and is relatively cheap.

- Fine stranded - fine stranded cable is preferrable when working with batteries or in tight spaces as it is easier to bend/work with.

- Solid - typically only used for indoor wiring. Slightly cheaper than stranded wire, but most difficult to bend/work with. Should not be used any larger than 10AWG/4mm².

- Bare (no insulation) - a cheap and durable option that can be used as part of a grounding system outdoors without a conduit if in a location where it will not be damaged.

Insulation and conditions of use

These classifications should be printed on the side of any wire or cable, although the exact terminology may vary based upon location. Below are some of the designations that are commonly used for wires used in offgrid PV installations.

| Classification | Common designation |

|---|---|

| Maximum insulation voltage | 600V, 1000V, 2000V |

| Heat resistance | 60°, 75°, 90° |

| Durable thermoplastic insulation | T |

| Synthetic polymer, flame-resistant | X |

| R | Rubber or Neoprene insulation |

| Heat resistant up to 75°C | H |

| Heat resistant up to 90°C | HH |

| Rated for use in wet locations | W |

| Nylon-coated to resist damage from oil or gasoline | N |

Common wire types used in offgrid PV installations

There are countless different types of wire, but there are only a few types that are commonly used on offgrid PV installations:

| Designation | Characteristics | Use |

|---|---|---|

| THHN/THWN | Rated for up to 90° in wet or dry locations. 600V rating. Available in nearly any size. | Used for circuits of any kind - inside or outside - within a conduit. |

| RHH RHW, or XHHW-2 | Flexible insulation rated. Characteristics may vary. | Battery wiring |

| PV wire/USE-2/RHW-2 | Rated for up to 90° in wet or dry locations. Can be exposed to sunlight. Voltage rating 600-2000V. Typically only found in certain sizes (12AWG, 4mm², 10AWG, 6mm²) | Wiring of PV source and from PV source to combiner box or charge controller. |

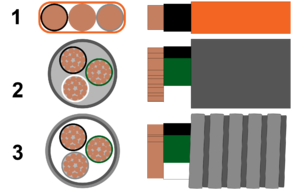

Cable types

All circuits involve more than one wire, therefore using cables that include multiple cables can save time and reduce costs on installations. Additionally, using cables of this type brings advantages that single wires do not offer.

| Type | Characteristics | Use |

|---|---|---|

| Non-metallic indoor rated | A varying number of wires of a choosen size bundled inside of a flexible plastic jacket or fused together. Cheap and easy to work with, but should only be installed in locations where it is protected from damage or in a conduit if it is an appropriate type of cable to be used in a conduit. | Used for indoor circuits in protected locations. |

| Direct burial cable | A varying number of wires of a chosen size bundled inside of multiple layers of insulation that provide excellent protection against damage, water and degradation. Can be directly buried underground without conduit if at a sufficient depth. Cheap and easy to work with. | Outdoor circuits that need to be run underground. |

| Metal clad indoor rated | A varying number of wires of a choosen size bundled inside of a flexible metal jacket. More expensive than other cable options, but provides superior protection. | Indoor wiring that needs to be protected. |

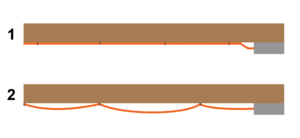

Securing and supporting wires and cable

Wire and cable do not always have to be run in conduit if they are not in a location where they will be exposed to damage, like an attic or under a PV module. If they are not run in conduit, they still must be properly secured and supported appropriately. The electrical code for the location will specify the minimum distance between supports, although the appropriate distance between supports should uttimately be determined based upon what will offer the most protection from accidental contact or damage from friction. Cables and wires should be snug against the surface they are being run against rather than drooping or dangling, although they should not be so tight that they are being significantly strained between supports. It is important to offer additional support near junction boxes as strain placed near a connection can lead to its failure.

Projected life

If wire is installed under proper conditions and not damaged, it should last for decades. Sunlight, abrasion or excessive movement will gradually destroy any type of wire.

Maintenance

All wiring should be checked at least once a year to make sure that it is not deteriorating or on the verge of failure.

Recyclability

Wire contains copper and aluminum, both of which are valuable metals. Wire can be recycled in major cities in nearly any part of the world at many different scrap facilities.

Notes

- ↑ Multi/Cable wire abbreviations and descriptions https://www.multicable.com/resources/reference-data/wire-abbreviations-and-descriptions/