Inverter sizing and selection

The inverter is sized and selected almost completely based upon the power demands of the user outlined in the AC load evaluation. The size of the PV source does not affect the size of the inverter and the energy storage system is only a concern if its capacity is significantly undersized relative to the size of the inverter as all types of batteries have a maximum amount of discharge current that they can safely supply.

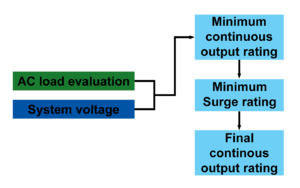

The basic considerations for sizing and selecting an inverter are the following:

- The input voltage must match the DC system voltage.

- The inverter should be able to meet the continuous power demand for all loads that will operate at the same time.

- The inverter should be able to meet the continuous power demand for all loads and the surge power demand for all loads that will operate at the same time.

This process is intended to serve as a guide, but the best option for a particular project will largely depend upon the available inverter sizes, the cost, and the particular project. There are a few common cases in which one may choose a different inverter size than is suggested here:

- It may make sense to buy an inverter that is smaller than is suggested by this process to keep costs low as the next size of inverter is significantly more expensive or would require the addition of an additional inverter that is stacked or added in parallel. In this case the users that they will have to manage their loads to avoid overloading the inverter. This makes the most sense with large infrequent loads that the users turn on and off. This approach is not recommended for projects that have large loads that may operate automatically - like a well pump or a refrigerator - as these loads are difficult to manage.

- It may make sense to buy an inverter that is larger than is suggested by this process to enable system expansion in the future or new additional loads.

Contents

Step 1: Determine the inverter continuous output rating

All inverters have a continuous output (duty) rating that can be found in volt-amperes (VA) or watts (W) on their specifications sheet, which is the capacity that the inverter has to continuously supply loads. VA = volts × amperes, just like Power (P) in watts, but is used to account for power factor. Regardless of the value used by the manufacturer (VA or W), the continuous duty rating of the inverter should exceed the total power requirement for all loads including power factor from the AC load evaluation.

| Minimum inverter continuous duty rating | = Total VA |

|---|

Step 2: Determine minimum inverter surge rating

Inverters also have additional capacity, called a surge rating or peak power rating, that can be used for short periods of time to supply surge loads. This additional capacity may be found in volt-amperes (VA) or watts (W) and will often have a time interval (1 second, 5 seconds, 5 minutes, 30 minutes). Regardless of the value used by the manufacturer (VA or W), the 1 second surge rating or peak power rating of the inverter should exceed the total power requirement and surge requirement for all loads from the AC load evaluation. The 1 second rating is the most relevant as the majority of the surges created by loads used with an off-grid system will have surges that are short in duration. The 30 minute value can be of interest if the size of the inverter is very close to the Total VA rating from Step 1.

| Minimum inverter surge rating | = Total VA with surge watts |

|---|

Step 3: Determine final inverter continuous duty rating

The chosen inverter should:

- Match the DC system voltage.

- Have a larger continuous output rating than determined in Step 1.

- Have a larger surge rating than the determined in Step 2.

Step 4: Verify that maximum continuous current of inverter is acceptable

The energy storage system must be large enough to be able to supply the continuous current that the inverter requires. Using an inverter that is oversized relative to the energy storage system can damage the batteries and can cause the system to function improperly. It is recommended that the continous current required by the inverter not exceed .13 (13%) of the Final Ah capacity of the energy storage system for lead acid batteries and .2 (20%) for AGM batteries. If this value is exceeded, then the size of the energy storage system should be increased.

| Maximum recommended discharge current | = Final Ah capacity × (.13 for FLA and gel batteries, .2 for AGM batteries) |

|---|

| Inverter continuous duty input current | = Final inverter continuous duty rating (Step 3) ÷ DC system voltage ÷ Inverter efficiency parameter |

|---|